For Reciprocating Coders we offer the "tried and true" Sprinter Marking Unit. A standard in contact coding for many years, it has been used to code anything from bread bags to brake pads.

Click here to see a video on the Sprinter Coders

Sprinter Marking Coders

Sprinter Marking offers both in-line and off-line code-marking machines. The in-line machine is independently mountable and offered in eight standard models of various sizes of marking heads. The off-line model is a stand alone benchtop model that may use any one of the eight standard Sprinter models. It comes assembled for immediate operation after air supply attachment, electrical plug in, and ink supply charging is completed. A foot switch is standard.

TYPES OF MARKS:

Date / Product Coding

Dot / Spot marking

Logos / Symbols

Sell-by / Use-by dating

Expiration date

Pricing

PRODUCTS MARKED:

Plastic, metal, glass

Rubber products

Paper

Cardboard

Flexible / Rigid containers

Films

SURFACES MARKED:

Porous

Non-porous

Stationary

Moving (limited)

Flat

Curved / Round (limited)

MACHINE FEATURES AND BENEFITS:

Simple design

Compact design

Lightweight marking head

Hardened wear surfaces

Hardened rods / bearings

Smooth / repeatable marking

Mounts in confined areas

Low pressure / better marks

Millions of cycles

Smooth action / minimum wear

MACHINE ACTION:

Double acting air cylinder

Small air cylinder

Unique / patented motion

Specially selected spring to rotate marking head

Optional magnet-on-piston air cylinder (all except model 22)

Optional flow controls mount on the air cylinder Controlled cycling action

Minimal compressed air

Smooth / high speed marks

Assures millions of cycles before replacing

Option of Hall / Reed effect switch to sense positions

Variable speed control in either direction

MARKING HEAD:

Removable / rotate-able marking head

Rubber marking type / dies

Easy, quick message change / repositioning

Excellent ink imprints

INK SUPPLY:

Quick-change ink reservoir

Sealed ink system

Durable quick-change ink pad

Clear ink bottle

Screw-on ink bottle

Modified reservoir

Fast change of ink supply

Immediate start up

Uniform prints / low cost

Supply level visible

Quick / easy changes

Upside down marking

MOUNTING ARRANGEMENT:

Two standard brackets / three mounting options

Narrow profile brackets

One tool bracket adjustments

Complete range of alignment

Mounts in confined areas

Quick / easy alignment

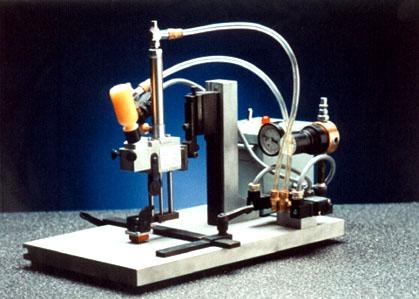

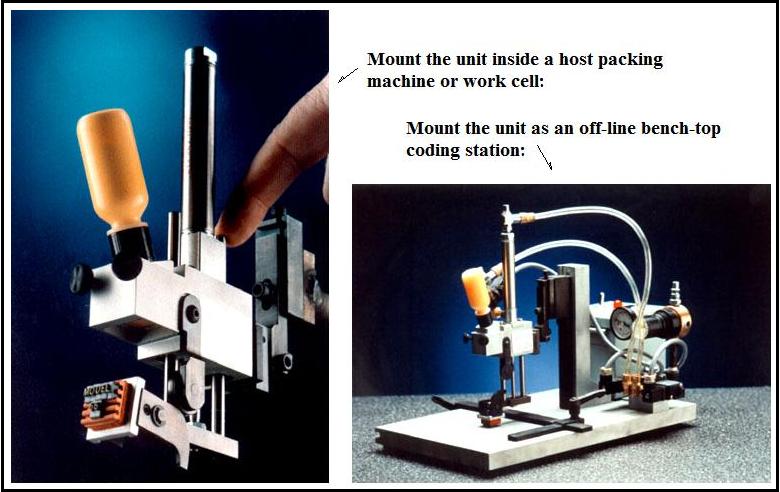

Model CC100 Contact Coder

Reciprocating Coder System

For intermittent coding operations, the Contact Coder prints logos, product codes, expiration dates, prices, etc. on boxes, bottles, cans, glass jars, plastic bags, metal parts and more. The versatile Contact Coder ink marks on a variety of substrates including plastic, metal, glass and paper. Pneumatically operated, the Contact Coder is a reciprocating printer that marks products and packages at rates up to 160 items per minute. The unit uses a gentle touch printhead that does not distort the type resulting in clear, crisp codes.

The Contact Coder can be integrated easily with form, fill & seal equipment, as well as with bagging and cartoning operations to form a complete packaging system. Additionally, the Contact Coder is well-suited

for industrial part identification and can be integrated into automated manufacturing lines. For manual operation, the two bench top models are ideal as stand-alone part marking stations.