Direct Printers

The Model 5324 Direct Printer is a marking system designed for continuous materials. During operation, a film of ink on the surface of the Ink Roll is transferred to the character face of the Type Wheel, which is then transferred onto the Printed Material.

Our Model 5324 Direct Print is designed for continuous printing on web materials, such as plastic film, sheet metal, wallboard, paper, foil and rubber. Using precision-molded rubber dies and high-contrast inks, it is an economical and simple solution for many coding applications. In operation, the lightweight, yet rugged unit, is driven by frictional contact with the material to provide continuous printing up to speeds of 600 feet per minute. With few adjustments and no complicated programming, the unit is easy to install, operate and maintain. The 24" circumference type wheel has a width of 3" to accommodate a variety of character styles and sizes. For a highly-professional, decorative touch, almost any type of font or logo can be reproduced. Click here for a brochure on the 5324.

Click here to see a video of the 5124 (12" wide) printing onto paper.

Click here to see the 5324 (3" wide) printing onto plastic bags.

Click here to see the 5324 printing with white ink onto a continuous web:

PRINT FEATURES

Print speed: 600 fpm (183 m/min)

Print width: up to 3" (76 mm))

Printing circumference: 24" (609 mm)

INKS

Colors: black, blue, brown, green, grey, orange, purple, red, silver, white and yellow

Formulas: standard and fast-drying inks for porous and non-porous surfaces including metals, fabrics, vinyls, plastics and more.

Capacity: one quart bottle (.95 liter)

Dimensions: (with ink bottle) 10.8" W x 18.1" L x 11.2" H (275 x 460 x 285 mm)

Weight: 35 lbs. (15.88 kg)

OPTIONS

- Lift bracket/printing pressure adjustment

- Pivot shaft drive

- Automatic Pump House for use with five gallon (18.9 liters) container of ink

- CE-approved cover

- Custom width printers available

Offset Printing

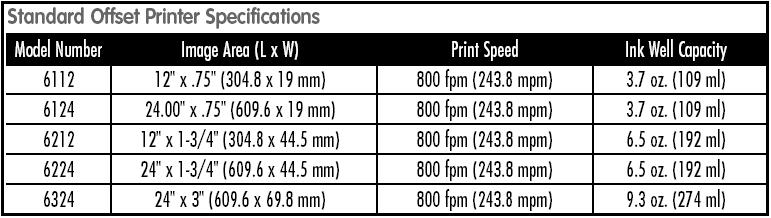

Matthews was one of the early Pioneers that designed and manufactured industrial quality, offset printers. This term offset printing means that a mark made by ink is transferred from a solid rubber covered roll, commonly referred to as a blanket roll. Offset printers are three roll systems that incorporate an ink roll, type wheel, and blanket roll. The type does not come into contact with the product on an offset system.

Matthews was one of the early Pioneers that designed and manufactured industrial quality, offset printers. This term offset printing means that a mark made by ink is transferred from a solid rubber covered roll, commonly referred to as a blanket roll. Offset printers are three roll systems that incorporate an ink roll, type wheel, and blanket roll. The type does not come into contact with the product on an offset system.

This system minimizes the amount of type wear while producing a permanent, consistent quality mark. The Print-A-Mark Offset Printer line is offered in 1", 2" and 3" wide roll units. Our standard printers are generally friction driven, obtaining their power from coming into contact with the product causing the product to revolve the printer.

Motor drive package options are available for applications that require an assist to revolve the offset printer. This is sometimes necessary when the product has a small diameter or too little friction available at the blanket roll contact point.

Click here for a brochure of the Off Set Printers.

Video of the 6124 printing onto rubber hose here: